Source: News Center, Publicity Department

By Li Xiang, Wang Qing

Recently, Prof. Wang Qing and her team members from the School of Materials Science and Engineering, Dalian University of Technology have made important progress in computational simulation and machine learning. Prof. Wang’s research group has been devoted to the design and development of high-performance alloy materials. Based on the cluster structural model proposed by Prof. Dong Chuang as the “materials genome”, the group has formed a practical cluster formula approach for composition design, which has improved the alloy development efficiency and developed a series of high-performance engineering alloy materials.

The properties of the materials are closely related to the microstructure at multiple scales, mainly including elemental combinations and gene units. In the previous work, the group used the creative cluster-based composition design approach to achieve the modulation of the microstructures of alloys. For the first time, the special coherent microstructure of cuboidal B2 nanoprecipitates in the body-centered-cubic (BCC) matrix was obtained from experiments by composition design, showing excellent mechanical properties at both room and elevated temperatures. This work was published in 2018 in Acta Materialia, a top international journal in the field of metallic materials, and ranked as a “highly cited paper”. Based on this, the phase-field method was applied to simulate the evolution of BCC/B2coherent microstructures of Al-Ni-Co-Fe-Cr high entropy alloys, which could reveal the composition correlation mechanism related to the microstructure, and then achieve the regulation of the macroscopic mechanical properties of the materials, resulting in the composition design of advanced engineering alloy materials oriented to performance goals. Currently, the work has been published again in Acta Materialia with the theme of “Phase-field simulation of coherent BCC/B2 microstructures in high entropy alloys”.

Figure.1 Coherent microstructures of alloys designed by cluster formula approach and their phase-field (PF) simulations

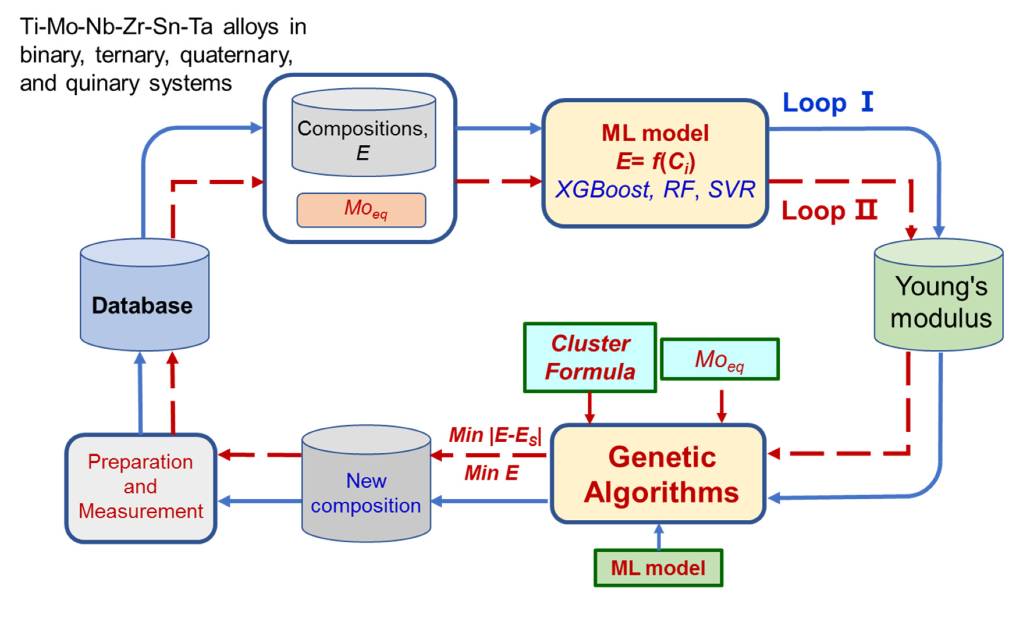

Meanwhile, in the development of the ‘Materials Genome Project’, multi-scale computational materials science has highlighted the advantages of rational design, in which characteristic-parameter-assisted machine learning (ML) method exhibits unique potential for developing high-performance engineering alloys. However, these parameters are not directly correlated to the composition, which could expand a composition search space as predicting new alloys in a performance-oriented manner and then make experimental validation more difficult. The group solved the above problem using their cluster formula approach, which could effectively improve the prediction accuracy of ML. In the latest work, the correlation between the composition (ci) and property (Young’s modulus E) was systematically constructed by ML, and the ML predictions were also validated experimentally. It was found that the cluster-formula-embedded ML model can make the prediction and optimization of composition and property more accurate, effective, and controllable. Currently, the work has been published in npj Computational Materials, a top international journal in the field of computational materials, with the theme of “Cluster-formula-embedded machine learning for design of multicomponent b-Ti alloys with low Young’s modulus”.

Figure. 2 Schematic diagram of the design of multicomponent b-Ti alloys with low-E based by machine learning

The first authors of these two papers are Li Jinlin and Yang Fei, respectively, master’s students of the School of Materials and Engineering, and the corresponding authors are Wang Qing from the School of Materials and Engineering and Li Zhen from the School of Mechanical Engineering. In addition, Prof. Dong Chuang from the School of Materials and Engineering and Prof. Peter K. Liaw from the University of Tennessee (USA) participated in the discussion of the working ideas.

Links to the papers: DOI: 10.1038/s41524-020-00372-w;

DOI: 10.1016/j.actamat.2020.07.030

Editor: Li Xiang