The State Key Laboratory of Fine Chemicals, subordinate to Dalian University of Technology, was established after the approval of the State Development Planning Commission in 1989. After more than thirty years of development, the Laboratory has become an important base in leading scientific innovation in fine chemicals and supporting the development of fine chemical industry in China. It was twice ranked among Grade A by the State Key Laboratory Assessment in 2009 and 2014, remaining as the only outstanding lab among all the first-level discipline laboratories of Chemical Engineering (‘Grade A’ Laboratory: the top State Key Laboratories among others). At present, it has 106 permanent personnel, more than 1000 postgraduate students, five academicians and more than 30 national-level talents including Distinguished Young Scholars.

Aiming at the 2035 Long-Range Objectives, the Laboratory makes full use of its advantages in organizing professional talents and conducting scientific research to meet the requirements of An Outline of the National Medium- and Long-Term Program for Science and Technology Development (2006-2020) and cater to the layout of fine chemical industry in China. Guided by the principle of innovation-driven development, the Laboratory focuses on innovation and industrialization of key raw materials in fields such as medical health, new energy and optical and electronic information to make scientific research serve national strategies and meet local needs.

Major contributions:

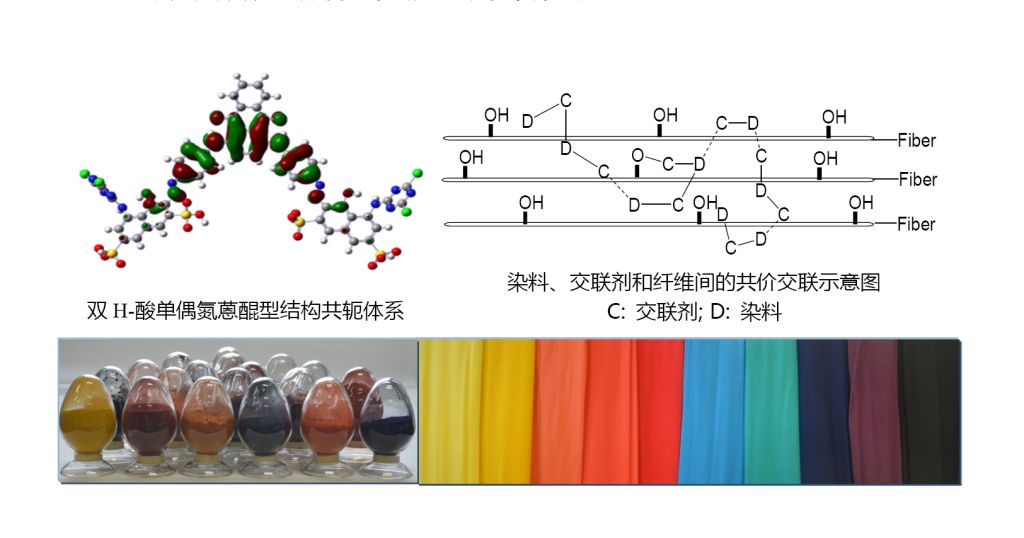

1. The Laboratory is the cradle of China's dye industry.Over the years, it has provided technical support for the development of textile dyeing industry in China and made important contributions to building China into a major country in textile and dyeing. The digital printing dyes have over 25% market share of the world's ink cartridges, and medical diagnostic dyes are widely used in hematology analyzer and exported to more than 90 countries. At present, it is getting over difficulties in EUV photoresist, flexible color display dyes, gene sequencing dyes, etc.

2. New materials made of high-performance polymers meet China's major needs.The high temperature resistant and soluble resin developed by the Laboratory is an indispensable material to aerospace. Other results, such as underwater sound absorption materials, radarwave absorbing materials, degradable carbon dioxide-based polymer materials, railway sleeper materials, etc., enjoy massive application and take the lead in related field. At present, it is making breakthroughs in key new materials including core parts of aircraft engines, nuclear pump shaft sleeves and high-capacity battery electrodes.

3. Intelligent Cleaning Process enjoys massive application.The non-porous diaphragm developed by the Laboratory has been applied to the recovery of petroleum tail gas and volatile organic compound gas, changing the process in China from being monopolized to accounting for the world's largest output. The Laboratory's share in the industrialization of methanol purification technology accounts for more than 90% of the national total. Additionally, more than 70 sets of facilities (10,000 tons/year) with low-carbon alkyl aromatization technology and carbon dioxide capture and purification technology have been extensively used in the industry.At present, it is focusing on key technologies such as experimental platforms for large-scale aircraft refrigeration system.